Engineers Committed to Your Design Objectives

At Alium Batteries, our dedication to continuous improvement and enhancement of our engineering capabilities propels us to deliver highly-engineered solutions for a broad range of applications. Boasting three decades of industry experience and a global team of highly qualified engineers specialized in various domains like mechanical, electrical, software, qualification, and compliance, we are equipped to support your project at every stage, right from conceptual design through to mass production.

Our engineering team comprises talented professionals possessing extensive knowledge and expertise in their respective fields. Our mechanical engineers excel in designing robust and efficient mechanical systems that guarantee optimal performance and reliability. Electrical engineers in our team are proficient in creating innovative electrical designs tailored to your application’s unique requirements. Our software engineers specialize in firmware development, communication protocols, and integration with host devices. Furthermore, our qualification and compliance engineers ensure that our solutions conform to industry standards and regulatory requirements, providing you with products that meet the highest quality and safety standards.

Operating from two Technical Centers in the U.S. and Asia, we offer a comprehensive array of engineering capabilities to support your project needs. Our key engineering capabilities include:

- Advanced Concept Development: Our advanced concept development services enable us to explore innovative ideas and solutions customized to your application’s specific needs. Leveraging our expertise and industry knowledge, we generate concepts that address your unique challenges, delivering optimal performance and functionality.

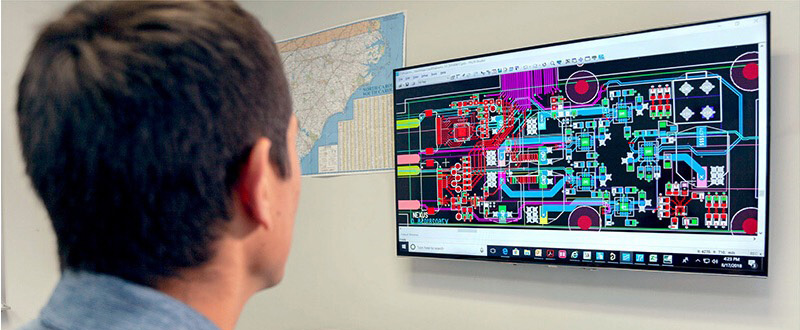

- In-House Design Capabilities: With our turnkey in-house design capabilities, we handle all aspects of the design process. Our expertise spans electrical, mechanical, software, and application design, allowing us to deliver complete system solutions. This includes designing battery packs, chargers, power supplies, inverters, and adapters, ensuring seamless integration and compatibility within your system.

- Battery Management System (BMS) Design: We specialize in in-house BMS design and customization. Our experienced team can develop BMS solutions tailored to your specific battery pack requirements, ensuring optimal performance, safety, and longevity.

- Prototyping Capabilities: We have in-house prototyping capabilities, including 3D printing. This enables us to rapidly iterate and validate designs, facilitating faster development cycles and quicker time-to-market.

- Compliance with Safety Standards: All our products are designed to meet the highest safety standards. We adhere to guidelines laid out by Underwriters Laboratories (UL) and Technischer Überwachungsverein (TUV), ensuring compliance with their respective certification requirements. Our designs undergo rigorous testing and evaluation to meet the standards specified by UL and TUV, providing you with products that are safe, reliable, and of the highest quality.

Collaborating closely with you to understand your requirements and goals, our global engineering team offers diverse perspectives and expertise, enabling us to tackle complex challenges and provide innovative solutions tailored to your specific needs.

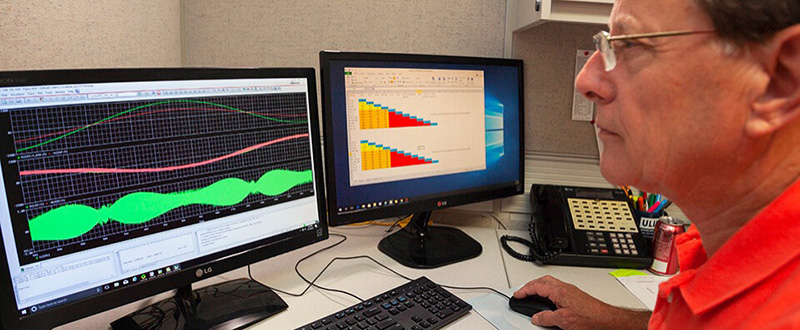

From the initial conceptual design phase, we harness our engineering capabilities to develop detailed designs that align with your specifications. Utilizing advanced tools and technologies, including computer-aided design (CAD) software, simulation tools, and rapid prototyping, we optimize the design and ensure its feasibility.

Throughout the development process, our engineers conduct rigorous testing and validation to verify the performance, reliability, and safety of the solutions. Leveraging our in-house testing facilities and expertise, we conduct a wide range of tests, including environmental testing, electrical testing, and compliance testing, to ensure that our solutions meet or exceed industry standards and regulations.

As we transition from design to production, our engineering team collaborates closely with our manufacturing and supply chain experts to ensure a seamless transition and efficient mass production. We have implemented robust processes and quality control measures to ensure consistent and reliable manufacturing, focusing on delivering high-quality products at scale.

We are committed to engineering excellence and providing our customers with highly-engineered solutions that meet their unique requirements.

Application Experience

We understand that different applications have different needs, and we have the knowledge and resources required to design and develop power solutions that operate safely and correctly within their intended environment. Our application engineers work directly with our customers to understand their specific requirements and have experience meeting the following needs:

- Low to high power (up to 10kWhr)

- Portability / Wearability / Flexibility

- Modularity / Scalability

- High reliability / 24 hour use

- Extreme temperature performance

- Environmentally-friendly

- Backward compatibility

- Class I, II & III medical devices

- Waterproof to IP68

- Intrinsically safe

- Smart features/communications

- Fast charge

- Long life

- Low noise

- Manufacturability (DFM)

- User-friendly

- And more!

New Product Introduction & Gate Process

At Alium, we work with the world’s largest & most innovative brands to design, develop and manufacture advanced battery and power solutions for applications from convenience to critical. To ensure our products meet all quality, safety and functionality requirements, our team of global engineers and product managers follow our New Product Introduction (NPI). This stage gate process drives New Product Development (NPD) through 3 phases (plan, design & qualification) with quality, supply chain and document control playing a critical role throughout the development lifecycle. Our NPI conforms to our 5 part gate process.